Views: 13 Author: Site Editor Publish Time: 2025-08-29 Origin: Site

Wire rope slings are indispensable tools in various industries, such a construction, manufacturing, logistics and offshore operations. Among the different methods for wire rope slings, the aluminum sleeve pressing technique stands out for its unique advantages.

1. The Technology Behind Aluminum Sleeve Pressing

Aluminum sleeve pressing, as a method for terminating wire ropes, utilizes the principle of plastic deformation and volume transfer of metal . The process involves putting an aluminum sleeve around the steel wire rope and applying significant pressure through a dedicated mold and hydraulic press. This permanent deformation causes the aluminum to flow into the gaps between the strands and wires, creating a safe, integral unit that works as a single entity .

Compared with other terminal methods like steel sleeves or traditional splicing, aluminum sleeves offer a good balance of high strength, lightweight, and corrosion resistance.

2. Advantages of Aluminum Sleeve Cable Wire Rope Slings

The choice of aluminum sleeves for wire rope slings is driven by several compelling advantages:

●High Strength and Safety: The terminal formed by the correctly pressed aluminum sleeve has a breaking strength that exceeds it of the steel wire rope itself. During destructive testing, the wire rope typically fails before the sleeve slips or breaks, ensuring safety and reliability .

●Lightweight and Compact: Aluminum is much lighter than steel. This reduces the total weight of the sling assembly, easing manual handling and potentially reducing the load on lifting equipment. The compact profile of aluminum sleeves is also beneficial in narrow spaces.

●Excellent Corrosion Resistance: Aluminum naturally forms a protective oxide layer, witch has good corrosion resistance in various environments, that enhances the durability of the sling terminal.

●Cost-Effectiveness and High Efficiency: The pressing process is relatively fast and requires less specialized labor compared to hand-splicing. Aluminum is generally more economical than stainless steel for the sleeve material, making it a cost-efficient choice for many applications without compromising performance .

●Standardization and Versatility: Aluminum sleeves can be used with a wide range of wire rope diameters. This enables the manufacturing and maintenance of slings to achieve a certain degree of standardization.

3. Applications and Related Product Types

Aluminum Sleeve Cable Wire Rope Slings have a wide range of applications and are used in many fields.

●General Lifting and Rigging: They are fundamental in industries like construction (e.g., bridge cable crane systems ), manufacturing, and shipping for lifting and moving loads.

●Specific Sling Configurations:

-Soft Eye Wire Rope Sling: This type features a loop formed by the wire rope itself, often pressed with an aluminum sleeve to create a continuous, knot-free eye. The "soft" eye is flexible and is very suiteable for connecting hooks or other sling hardware. The aluminum sleeve provides a clean and reliable termination for such eyes.

-Wire Rope Sling with Thimble Eye: A thimble (a grooved metal ring) is often inserted into the eye of a sling. The main function of the thimble is to protect the wire rope from wear and bending fatigue by providing a supportive saddle for the rope and preventing it from kinking or pinching. Aluminum sleeves are commonly used to secure the ends of the rope after the thimble has been positioned, creating a durable and protected loop eye.

●Specialist Installations: The concept of a wire rope ceiling might involve using wire ropes for suspended installations, such as mounting equipment (e.g., Access Points ) or decorative elements from T-bar ceilings using tensioned wire ropes. While the loads here are typically much lighter, the principles of secure termination remain important. Aluminum sleeves offer a neat and reliable way to form loops or ends in such cables.

●Other Uses: Beyond slings, aluminum sleeves are also used in wire rope assemblies for applications like cable restraints in machinery, anti-drop systems for tools, and even in specialized cables (e.g., LIYCY-SU-TP-PUR types with steel wire rope reinforcement for tensile strength ) where terminating the strength member is crucial.

4. Selection and Standards: Understanding wire rope sling chart and HSN Code

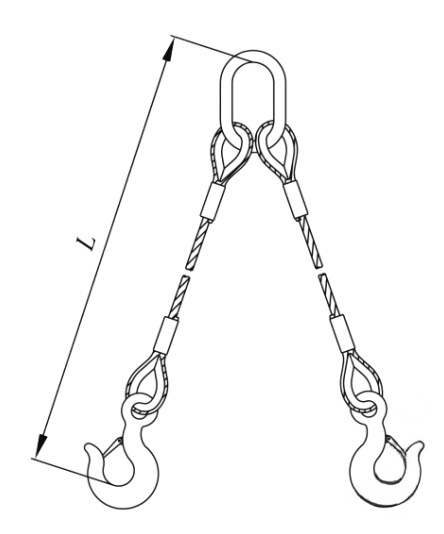

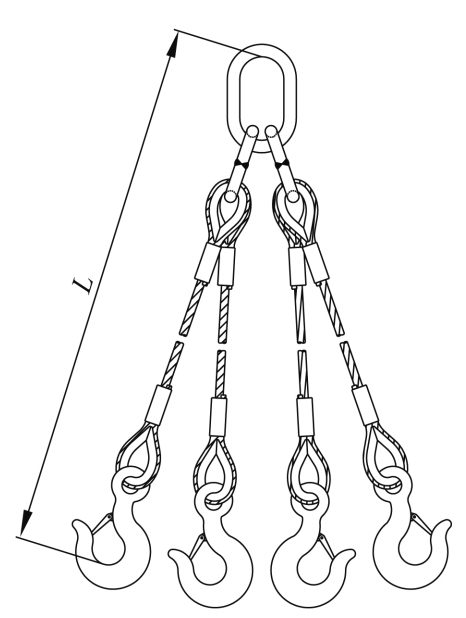

Choosing the right wire rope sling involves understanding its working load limit (WLL), which depends on the rope diameter, construction, and configuration (e.g., single-leg, two-leg bridle ).

●Wire Rope Sling Chart: Manufacturers provide wire rope sling charts or capacity charts. These charts are essential references. They usually list rope diameters, types (e.g., with or without thimble), configurations, and their corresponding WLLs at different angles. Make sure never exceed the rated WLL.

●Wire Rope Sling HSN Code: The Harmonized System Nomenclature (HSN) code is used for classifying goods in international trade. While the specific code can vary slightly based on exact product features, wire rope slings often fall under HS Code 7312 (e.g., 731210 for stranded wire, ropes, and cables). For example, a product listing for a steel wire rope sling mentioned HS code 7312102000 . Knowing the HSN code is crucial for import/export documentation and taxation purposes.

Table: Key Considerations for Selecting Aluminum Sleeve Pressed Wire Rope Slings

| Factor | Description | Importance |

| Working Load Limit (WLL) | Maximum load the sling is designed to handle. Determined by rope diameter, construction, and splicing efficiency. | Primary safety factor. Must never be exceeded. |

| Sling Configuration | Single-leg, multi-leg (2-leg bridle ), type of eye (soft, thimble). | Affects capacity and application suitability. |

| Rope Diameter | The nominal diameter of the wire rope. | Must be compatible with the aluminum sleeve size. |

| Sleeve Material & Quality | Aluminum alloy specifications, integrity of the press. | Ensures termination strength and durability. |

| Environmental Conditions | Exposure to moisture, chemicals, extreme temperatures (e.g., -60°F to +400°F range mentioned for a sling ). | Influences material choice (rope and sleeve) for corrosion resistance and temperature tolerance. |

| Compliance & Certification | Adherence to relevant national or international standards. | Ensures product quality and safety reliability. |

5. Conclusion

The aluminum sleeve pressing technique offers a superior combination of strength, safety, lightness, and economic efficiency for terminating wire rope slings. Whether for a standard wire rope sling with thimble eye, a flexible soft eye wire rope sling, or other configurations, this method provides a reliable and durable solution.