Views: 19 Author: Site Editor Publish Time: 2025-09-10 Origin: Site

In the demanding worlds of construction, manufacturing, and heavy logistics, the safe and efficient movement of materials is a critical operation. Among the essential tools for this task, chain slings for lifting stand out for their unparalleled strength, durability and versatility. However, their powerful capability is entirely dependent on one crucial factor: correct selection and application. Choosing the wrong lifting sling chain is not a simple mistake—it is a significant safety risk. This comprehensive guide details the key considerations for selecting the correct chain sling for any lifting operation, ensuring both safety and efficiency.

Chain slings for lifting are configured in various ways to match specific load types and lifting scenarios. The main configurations include:

● Single Leg Chain Sling: This is a basic assembly, consisting of a single length of chain with a sling hook or other fitting at each end. It is designed for directly and vertical lifting of balanced loads where the center of gravity is easily accessible.

● Multi-Leg Slings (2 leg chain sling, 3leg chain sling, or 4 Leg chain sling): These slings are characterized by multiple legs gathered at a top master link. They are indispensable for lifting large, heavy, or bulky objects (like machinery or containers) as they distribute the load's weight evenly across several connection points. The geometry of the lift is crucial here.

● Adjustable Chain Sling: This type includes a mechanical adjuster, allowing the user to quickly shorten or lengthen one or more legs. The adjustable chain sling offers exceptional flexibility for lifting irregularly shaped or unbalanced loads, making it a versatile choice for complex tasks.

● Sling Round and Other Configurations: In addition to the standard legs, slings can be configured in a basket or choke hitch. A basket hitch (or sling round method) cradles the load and can effectively double the sling's vertical rated capacity, while a choke hitch wraps around the load to secure a firm grip, though it reduces the WLL.

The grade of a chain defines the mechanical properties of the alloy steel from which it is made, primarily its yield strength. It is the most important indicator of its lifting capacity.

● Grade 80 (G80): The industry standard for overhead lifting chains and slings. It is heat-treated for high strength, excellent durability, and good resistance to impact. Every link is stamped with an "8" for identification.

● Grade 100 (G100): This grade offers a higher strength-to-weight ratio than G80. A G100 chain of the same diameter will have a higher Working Load Limit (WLL), making the sling lighter and easier to handle. It is marked with a "10".

● Grade 120 (G120): A premium-grade chain providing superior strength and further weight reduction for the most demanding applications.

Critical Warning: Never use Grade 30, 43, or 70 chains (often referred to as "transport" or "trucker" chains) for overhead lifting. These grades do not possess the necessary safety factors, durability, or shock load resistance required for safe lifting operations.

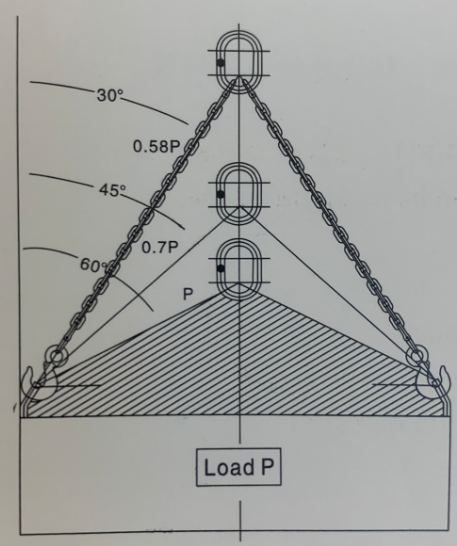

The angle between the sling legs is the single most critical factor in determining the actual tension on each leg. As the angle decreases, the tension on each leg increases dramatically.

The formula to calculate the load on each leg is:

Load on Leg = (Total Load Weight / Number of Legs) × (1 / Sine of the Angle)

● Example: Lifting a 10-ton load with a two-leg sling at a 60-degree angle.

-- Load per leg = (10 tons / 2) × (1 / sin(60°)) = 5 tons × (1 / 0.866) ≈ 5.77 tons.

-- The selected single leg chain or each leg of a multi-leg sling must have a WLL rated for at least 5.77 tons at this angle.

Always consult the manufacturer’s load chart, which clearly shows the derated WLL based on the angle. Ignoring the angle can lead to catastrophic overload.

Chain slings for lifting are the superior choice in several specific scenarios:

● High-Temperature Environments: Chains can withstand extreme heat (up to 400°C / 750°F for G80) without melting or degrading, unlike synthetic slings.

● Abrasive or Sharp Loads: Suitable for lifting steel coils, castings, and machinery with sharp edges that would quickly cut or fray a synthetic sling.

● Durability and Longevity: Highly resistant to UV light, chemicals, and abrasion, with a longer service life in harsh industrial environments.

● Heavy-Duty and Shock Loads: Excellent for applications with extreme weights and in punishing environments like foundries and steel mills.

● Chemical Exposure: While resistant, chains can be corroded by acids and alkalis. It is necessary to frequently check for corrosion pitting. In highly corrosive environments, stainless steel or specially coated chains may be required.

● Load Protection: To prevent damage to delicate load surfaces (e.g., polished finishes), use protective sleeves or corner pads. This also protects the chain itself from unnecessary wear.

● Extreme Environments: For offshore or sub-zero applications, ensure the chain grade certification is suitable for the expected temperatures.

Temperature directly affects the metallurgical properties and strength of a chain.

● High Heat: Grade 80 chains can be used up to 400°C (750°F). Between 400°C and 500°C (930°F), the WLL must be derated. Exposure above 500°C permanently damages the heat treatment, and the sling must be scrapped immediately. Evidence of heat damage includes blue/black discoloration and scale.

● Low Temperatures: Standard Grade 80 and 100 chains perform adequately down to -40°C (-40°F). However, the metal becomes less tough and more susceptible to shock loads. Special grades are available for cryogenic applications.

| Temperature | Due to the high temperature the WLL will reduce |

| -40℃~200℃ | The original 100% rated load |

| 200℃~300℃ | The original 90% rated load |

| 300℃~400℃ | The original 75% rated load |

| Over 400℃ | Not allowed |

How a sling is connected is as important as the chain itself. Use only certified, load-rated components.

● Sling Hooks: Must be equipped with a functioning safety latch to prevent the load from accidentally disengaging. Regularly check the hook throat for distortion or stretching.

● Master Links and Coupling Links: These components are used to assemble legs and must be of the correct grade and size, with a WLL matching that of the chain.

● Shackles and Other Hardware: All connecting hardware must be compatible and have a WLL at least equal to the sling leg it is connecting to.

Pre-Use Inspection (Every Shift): Conduct a thorough visual and manual inspection. Look for:

● Stretch (Elongation): Any visibly stretched links indicate overload and mandate immediate removal.

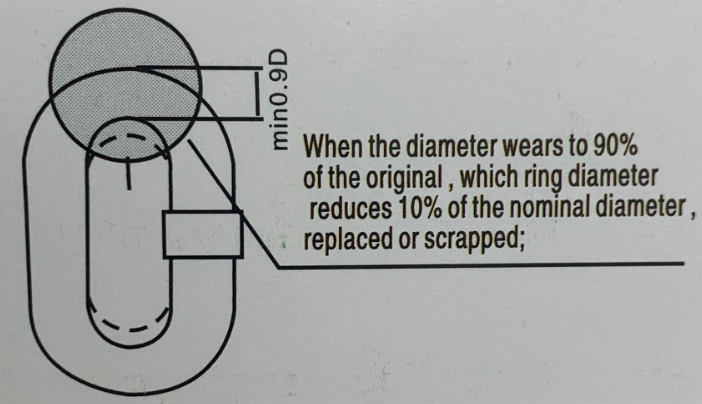

● Wear: Measure the chain diameter. Compare to the manufacturer's "discard" dimension.

● Nicks, Gouges, and Cracks: Any surface defect can be a stress riser.

● Deformed, Bent, or Twisted Links.

● Corrosion: Deep pitting is a cause for rejection.

● Hooks and Latches: Check for twist, throat opening, and latch function.

● Tag: Ensure the original identification tag is present and legible.

In-Use Precautions:

● Avoid shock loading by lifting slowly and smoothly.

● Ensure the load is balanced and stable before lifting.

● Never tip-load a hook.

● Keep hands and fingers clear from pinch points.

● Use tag lines to control the load from a safe distance.

Post-Use Storage: Hang chain slings for lifting on a dedicated rack in a clean, dry location. Proper storage prevents kinking, tangling, and unnecessary wear and corrosion.

A chain sling must be immediately removed from service and discarded if any of the following are found:

● When the diameter wears to 90% of the original, which ring diameter reduces 10% of the nominal diameter, replaced or scrapped (Figure 1). D=ring diameter, P=Pitch, L=outer length of the ting (Figure 2).

Figure 1 Figure 2

● The external length of the ring increased by 3%, which the internal length elongated by 5%, the parts of the sling should be replaced or scrapped (Figure 3).

Figure 3

● Any cracks be founded by naked eye or other equipment inspection link weldingm should replace the parts or scrapped (Figure 4).

Figure 4

● Twisted, serious corrosion and fouling, can not be ruled out, component parts of dangerous section of reducing the wear up to 10% of, the original size, replaced or scrapped;

● Single link pitch exceeds by 5% of the nominal, replaced or scrapped;

● It can not be used if damaged by heat resource.

● It can not continue to use after corrosion.

Selecting the correct chain sling for lifting is a disciplined process that merges technical knowledge with a steadfast commitment to safety. It requires a meticulous assessment of the load, the environment, and the fundamental principles of rigging physics. By understanding chain types and grades, respecting the critical importance of lift angles, and adhering to a rigorous protocol of inspection and maintenance, you ensure that every lift is performed with maximum safety and efficiency. The chain is only as strong as its weakest link; your diligence ensures that link never fails.